Innovative Solutions for Turbomachinery

Gas Foil Bearing Technology

Xeca is advancing 100% oil-free gas foil bearing technology for turbomachinery applications in data center cooling, refrigeration, heat pump, hydrogen fuel cell, oxygen/ nitrogen generation, and wastewater treatment.

Compared to screw compressors, Xeca dynamic gas bearing compressors offer significant advantages, including higher energy efficiency, reduced maintenance costs, lower noise and vibration, and a more compact, lightweight design.

Compared to magnetic bearing compressors, Xeca’s gas bearing technology eliminate the need for complex control system and backup bearings, making it more resilient during power outages and frequent start-stop operations.

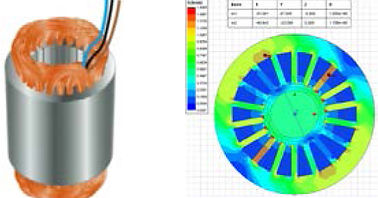

High-Speed Direct-Drive PMSM

The research team, utilizing the multi-field coupling design technology of electrical, magnetic, mechanical, and thermal fields, has independently developed a high-speed direct-drive permanent magnet synchronous motor (PMSM); They have solved high rotor heat generation, high torque ripple, and high motor noise and resulted in a motor with high reliability, high temperature resistance, and low aerodynamic drag loss; Additionally, challenges related to rotor structural integrity have been overcome, leading to the development of a high-power density, low-cost, and high transmission efficiency direct-drive permanent magnet synchronous motor.

High-Speed Rotor Dynamic Design

The high-speed rotor dynamics design assures stable operation of the rotor at high speed. This proprietary approach integrates the rotor structure with the motor aerodynamic and oil-free bearing design.

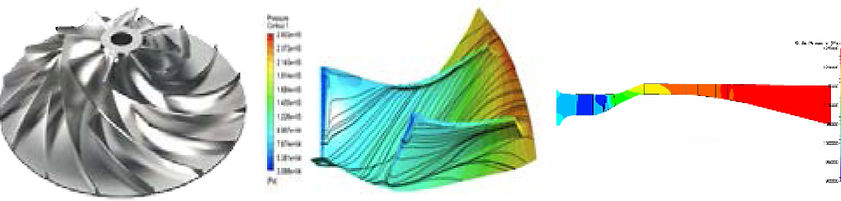

High Performance Aerodynamic Design

The centrifugal design features a high-efficiency three-dimensional impeller with a wide operating range, while the axial flow incorporates a double helix contraction type intake channel for axial intake. The intake guide vanes use a forward pre swirl design, and the rotating blades are designed with a composite curved sweep and wide chord design, achieving a high 80% efficiency.

Thermal Management

The R&D team applied the thermal management and optimization technologies from the secondary air system of aircraft engines across different fields, leading to the development of efficient and robust products.

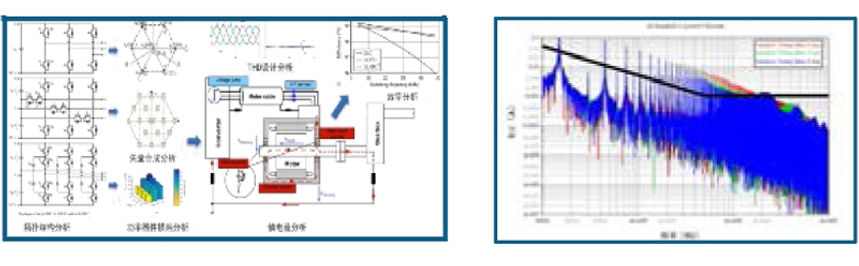

Efficient Drive Control

High-efficiency conversion topology, along with thermal multiphysics integration and electromagnetic compatibility technology has been developed for high-density electromagnetic machine. These advancements solve issues such as large switching losses, low efficiency, and poor electromagnetic compatibility. Additionally, they have developed high-speed permanent magnet vector control, decoupling, and delay compensation technologies that enhance system efficiency and reliability, resolve the problem of poor torque stability in high-speed motors, and provide an advanced control solution for high-speed permanent magnet motors.